But rather than superheating it to create cement (which would release all that CO2 right back into the atmosphere), Constantz and his team turn the resulting stone into pebbles that serve as aggregate. Calcium carbonate happens to be the main ingredient in limestone. In the process, the company creates carbonate that reacts with calcium from waste materials or rock to create calcium carbonate. Inspired by this phenomenon, he developed a similar “low-energy mineralization” technique that turns captured CO2 into the same bony stuff that corals secrete: calcium carbonate.īlue Planet’s process starts with collecting CO2 and dissolving it in a solution. Corals turn millions of teeny polyps into stunning, full-grown reefs through a process known as biomineralization, Constantz explained. The company’s technology, like his previous work, builds on the power of corals. Its goal is “economically sustainable carbon capture.”

That passion lead Constantz to launch a company in 2012 called Blue Planet, based in Los Gatos, California. His patents and products are used by doctors around the world.ĭeveloping and testing new medical procedures was perilous work, Constantz said, although the drive to cure terminal illnesses outweighed many of the risks involved.

It’s a massive undertaking, but if we change how we think about concrete, capturing a trillion tons of CO2 may not be so pie-in-the-sky after all.Įnter Brent Constantz, a Silicon Valley entrepreneur and marine geologist, who once treated cardiovascular calcification and created bone cements (used in operating rooms to mend broken limbs) by mimicking the process that corals and shellfish use to create their own shells.

The National Academies of Science agrees that “negative emissions technologies,” as they’re known, are essential. To do that, the Foundation for Climate Restoration estimates that a trillion tons of CO2 must be removed from our atmosphere on top of additional efforts to curb emissions. The technique, which has already been demonstrated in California, is part of a growing effort to not just slow the advance of climate change, but to reverse it, restoring a safe and healthy climate for ourselves and future generations. A new method of creating concrete actually pulls C02 out of the air, or directly out of industrial exhaust pipes, and turns it into synthetic limestone. We set a new CO2 record just last month, notching 411.66 parts per million of CO2 in the air in Mauna Loa, Hawaii - far higher than the 300 parts per million that is the highest humans have ever survived long-term.īut a solution on the horizon could switch up the math completely. It’s no secret that we have already blown past the levels of climate-altering pollution that scientists warn could have catastrophic effects on life as we know it. Cement production worldwide could grow another 23 percent by 2050.

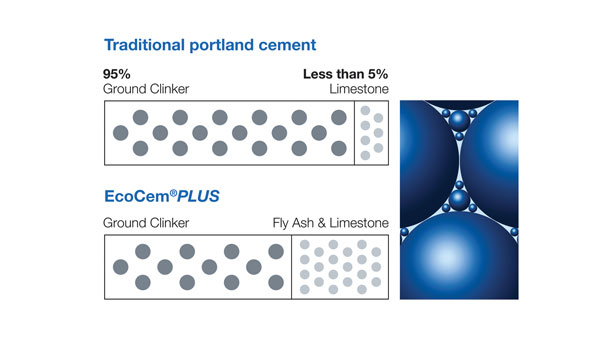

Between 20, China used more cement than the United States used in all of the 20th century - about enough to pave paradise and put up a parking lot the size of Hawaii’s Big Island. Add to that all the fuel burned to mine and crush the aggregate, and you’ve got a climate disaster.īy some accounts, concrete alone is responsible for 4-8 percent of the world’s CO2 emissions. Portland cement, the most commonly used base (the goop that gets mixed with sand and gravel, or aggregate, to form concrete), is made with limestone that is quarried and then heated to staggeringly high temperatures - releasing huge amounts of carbon dioxide in the process. It also happens to be incredibly bad for the climate. To support our nonprofit environmental journalism, please consider disabling your ad-blocker to allow ads on Grist.

0 kommentar(er)

0 kommentar(er)